Benefits

Why use Comrod’s mast system?

Comrod’s mast system has many advantages. We focus on all phases of a power line project – from the design and production of the masts to efficient foundation and installation. We offer a concept that provides both environmental benefits, significantly reduced risk of accidents and injuries to personnel, and a lower total cost for the customer.

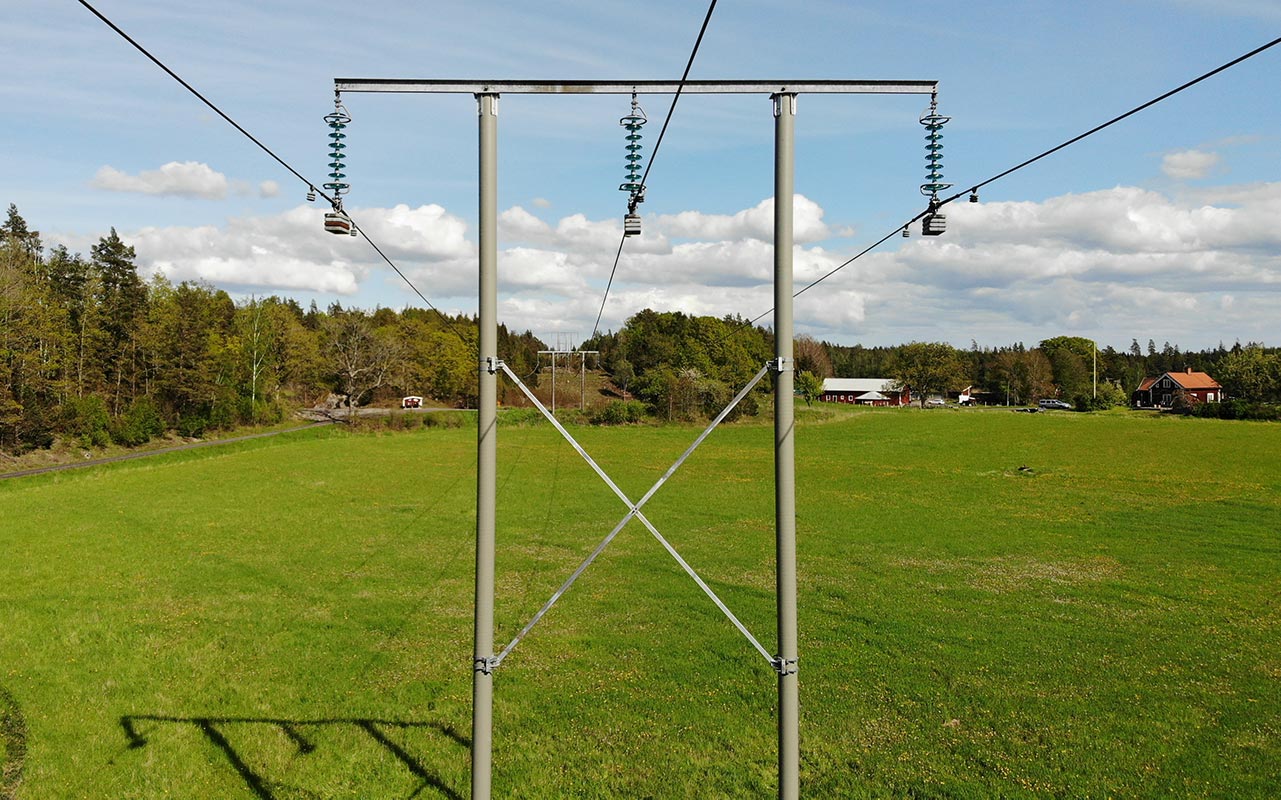

The mast system

Comrod’s composite poles have low weight, high stiffness and long lifetime. Modules and pole types can be easily optimized to satisfy the customer’s requirements for each individual mast position. We can supply single masts, H-masts, A-masts, triple masts and special masts. Our solutions cover voltage ranges from 22 kV to 132 kV.

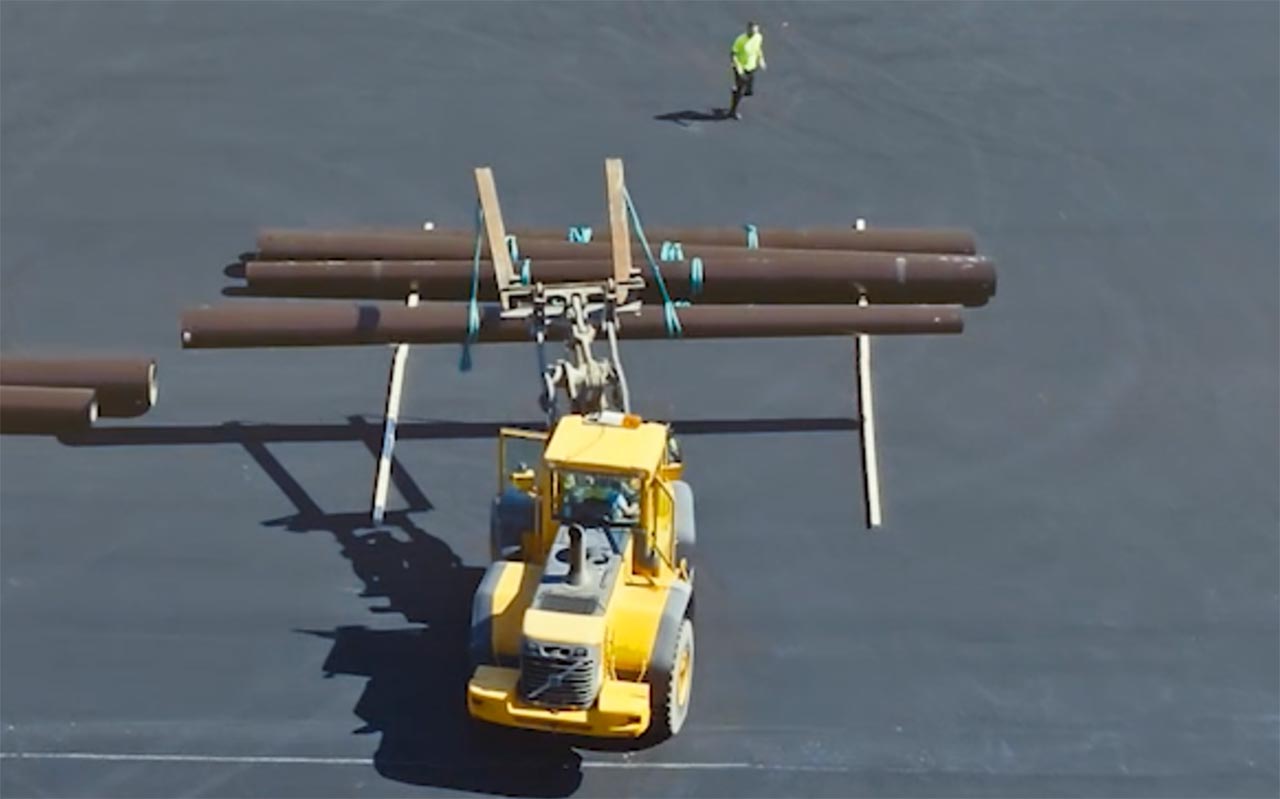

Unique foundation

Our self-developed method of slot drilling in rock is described by customers as a revolutionary foundation method -particularly where there is difficult access and steep and demanding terrain. All the methods we use allow installation work close to live cables and live lines.

Environment and safety

When the poles and installation equipment can be flown directly to the site by helicopter, you can avoid construction roads to the mast positions. Our foundation also provides a minimal footprint around the mast. In terms of HSE, it is also beneficial to avoid all forms of blasting and deep ditches.

Maintenance free

During the development, thorough analysis and testing of resistance to weather, fire, UV radiation and deformation have been performed . The composite masts are maintenance-free with estimated minimum lifetime of 80-100 years. It is still recommended to inspect the masts periodically as part of normal power line inspection.

Cost-saving and efficient

There are several aspects of our pole concept that make this a cost-saving and efficient solution. Light poles and equipment that can be flown to the site, avoiding the need for construction roads, and the stiffness of the mast and the foundation require fewer mast positions. Furthermore, the poles have a long lifetime and are virtually maintenance-free. We use our unique slot drilling foundation method, developed for demanding terrain, enabling us to install several mast positions at the same time.

Delivery time and flexibility

With a factory in Norway, we have a geographical proximity to the market that allows for flexibility in delivery and short delivery time. With full control over the production of the masts and the foundation, as well as experienced engineers, we can deliver even highly customized masts.

Do you want to know more about our poles and foundations?

Please contact us for more detailed product presentations, technical descriptions or videos from our full-scale tests. You are of course also welcome to visit us at Tau outside Stavanger.

EXTENDED PRODUCT PORTFOLIO:

Jerol Industri - our Swedish sister company

Jerol Industri became part of the Comrod group in the spring of 2021. Jerol has a product portfolio that complements Comrod's portfolio of composite masts for the distribution and regional network.